The 6-Second Trick For Sheroz Earthworks

Table of ContentsGetting The Sheroz Earthworks To WorkNot known Incorrect Statements About Sheroz Earthworks The 25-Second Trick For Sheroz EarthworksThe Single Strategy To Use For Sheroz EarthworksThe Single Strategy To Use For Sheroz Earthworks

For any type of earthwork service provider, it is essential to carry out collaborate with high quality, accuracy, and on timetable. Utilizing device control in job machines makes it possible for enhancing the different phases in the earthwork process, from planning to the upkeep stage - trimble gps. The equipment control system assists the device operator in attaining the target aircraft promptly and quickly

The machine control system guides the driver with centimeter precision. With Xsite PRO 3D, you'll constantly know exactly just how much to cut or load. Your local Xsite technical assistance can assist you and assist with any kind of problems without going to the site. Remote assistance conserves money and time, as it lessens downtime in jobsites.

Getting My Sheroz Earthworks To Work

Our system's elements are thoroughly made to withstand the harsh conditions of building sites. Comparison of the same project executed using maker control versus the conventional approach reveals that, on average, the traditional method requires 50% even more time to complete the very same job as the technology-assisted method.

Sounds great, ideal? Go into the Xsite maker control system; it's right here to give you with a significant benefit when collaborating with earthmoving equipment. Discover just how Xsite Equipment Control can enhance your performance and make certain job safety! We understand that learning a brand-new innovation might feel like a drag, yet don't fret! Our friendly and specialist regional assistance services have obtained you covered, making sure that you can maintain working smarter without disturbances while on duty! Through remote assistance, your neighborhood Xsite dealership can provide advice or troubleshooting without needing to visit the website! What type of excavators does machine control fit? Xsite Maker Control systems can be mounted to any type of excavator from mini excavators to large mining excavators.

Just how does machine control work? In 2D systems, the device is geared up with adjusted inclination sensors.

The system is very simple to learn the fundamentals can be taught in under one hour of training. With Xsite you don't have to fret about finding out all the pointers and technique simultaneously. Extra training and guidelines are constantly available over remote assistance when needed. Call your neighborhood Xsite supplier to discover even more! Just how does the remote support work? A cordless web connection makes it feasible to establish a remote connection between the equipment control system and the service.

Sheroz Earthworks Things To Know Before You Buy

What sort of data styles Xsite systems assistance? Xsite Maker Control systems support open typical data formats, making it possible for smooth information circulation from one system to another. Sustained documents styles: 2D-Maps: DXF Point files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What components are installed on my machine? Depending on your selection of system (with or without placing, i.e - topcon., 2D or 3D), your machine is equipped with disposition sensors, a controller unit, and a display/operating panel.

Several equipment and software solutions exist to assist figure out a device's present placement on the earth and compare it with a wanted design surfaceand building drivers can do even more to leverage the benefits. Machine control is the use of various placing sensors and a screen to offer the driver my review here with a referral between the placement of the pail or blade and the target quality.

Relying on the configuration, device control systems can supply the driver with a simple visual guide to pail or blade position, or can instantly relocate the blade to grade by talking with the equipment's hydraulics - https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks. There are equipment control systems readily available for nearly any equipment: graders, dozers, excavators, soil and asphalt compactors, scrapes, trimmers, crushing equipments, and pavers

The smart Trick of Sheroz Earthworks That Nobody is Talking About

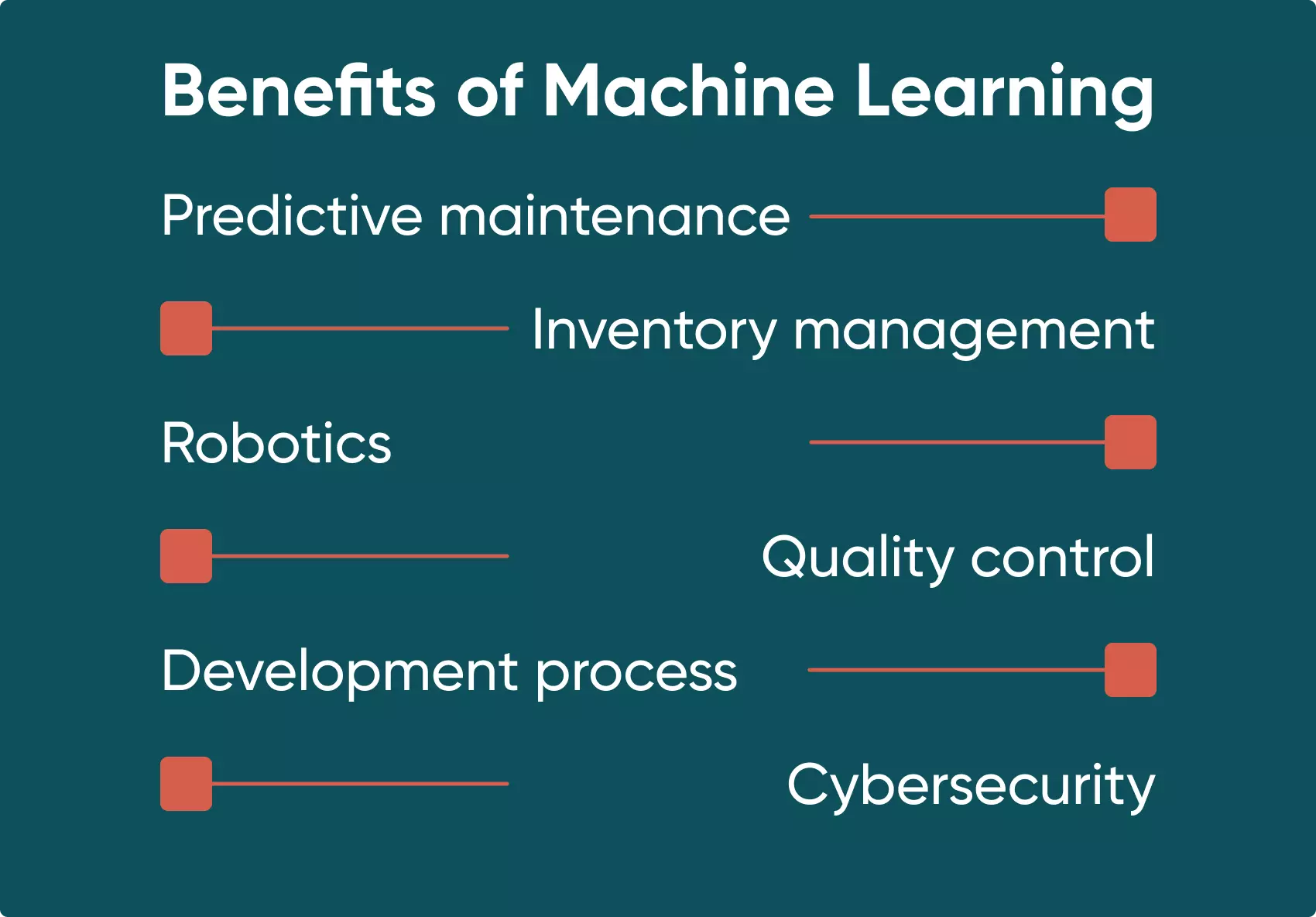

Some benefits consist of lowered rework, boosted task effectiveness, and lower evaluating prices. Machine control can additionally assist enhance productivity and lower general expenses. This innovation is transforming the means the building sector works. Building and construction equipment without machine control will certainly become a distant memory and the advantages obtained from it will certainly be numerous.

Trimble maker control systems give a myriad of benefits to any person who utilizes earthwork machinery and, at EarthCalc, we can supply you with 3D apply for your device control-enable equipment. Not sure if machine control deserves the cost? Take into consideration the following reasons you need to consider this alternative.

Making use of GPS straightened with your 3D design documents, these systems essentially ensure that you will certainly eliminate or put the correct quantity of material at the building website. On many building websites, rework is a typical and irritating reality, but with Trimble device control, you can remove the need for rework.

Getting My Sheroz Earthworks To Work

Usually, with Trimble maker control, you can get rid of excess tools at a specific work website. A job that might have needed the use of 3 or 4 items of digging deep into tools currently may need just two items of devices to accomplish the very same task in much less time. This enables you to move your equipment to one more work website and deal with several tasks at one time.